Is the cross-border certification for silicone protective cases incomplete?

A Must-Read for Manufacturers! Guide to Cross-Border E-Commerce / Foreign Trade Export Certification

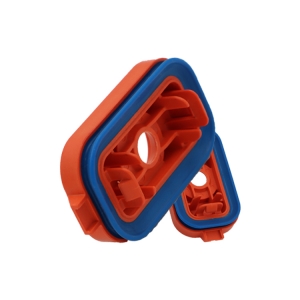

Enterprises engaged in cross-border export of digital accessories often face problems such as customs detention and platform removal due to the lack of certification for silicone protective cases. This not only results in the loss of goods costs but also affects the brand’s overseas reputation. In fact, as long as you identify the certification standards of the target market and supplement the qualifications accordingly, you can ensure that silicone protective cases are successfully exported.

Step 1: Clarify the certification requirements of the target market. For exports to the EU, REACH chemical testing and RoHS environmental certification are required. Children’s silicone protective cases also need to undergo EN 71 toy safety testing. The North American market must comply with FDA food-grade contact standards (if involving children’s products) and CPSIA certification. For emerging markets such as Southeast Asia and the Middle East, it is necessary to confirm the material safety requirements of local customs in advance to avoid rejection due to non-compliance with standards.

Step 2: Strictly control the compliance of the production process. When producing silicone protective cases, it is necessary to use environmentally friendly raw materials to prevent excessive levels of harmful substances such as heavy metals and phthalates. Entrust authoritative third-party institutions for testing to obtain formal certification reports, and avoid the traps of “forged certificates” and “oral compliance”, ensuring that the reports can be queried and verified on official platforms.

Step 3: Properly file the certification documents. Compile the certification reports and test data of various markets into volumes, attach them to the goods during cross-border shipment, and display the certification marks on the details page of the e-commerce platform. This can not only enhance consumers’ trust but also cope with random inspections by customs and platforms.

The core of cross-border compliance for silicone protective cases lies in matching the certification standards of the target market. If you are a digital accessories manufacturer worried about product export certification, please feel free to send a private message or call us for cooperation! Inform us of the export region and product model, and we will provide compliant production solutions and certification assistance to help your products pass customs smoothly and seize the overseas market!