Don’t just look at the price when purchasing liquid silicone overmolding! These 3 hidden parameters are the key to quality

Purchase of liquid silicone overmolding: 3 core parameters determine the quality of the finished product

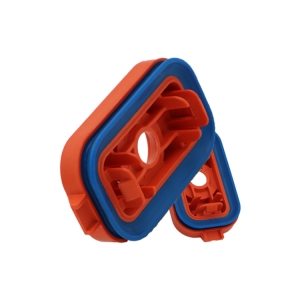

Liquid silicone overmolding, with its excellent sealing performance (IP68 waterproof rating) and skin-friendly, soft touch experience, has become a “standard process” for products such as medical catheters, maternal and infant products, and electronic components. However, many manufacturers focus solely on the quotation when purchasing, while ignoring three hidden parameters that determine the quality of the finished product. As a result, either the defective rate of the finished product soars to more than 15%, or there are frequent after-sales disputes later, leading to a sharp drop in customer repurchase rate.

Take a medical enterprise in Shenzhen that produces insulin pump components as an example. Initially, to control costs, it chose low-cost liquid silicone overmolding materials. As a result, during ethylene oxide sterilization (high-temperature and high-humidity environment), the overmolding layer peeled off from the substrate on a large scale. Later, after replacing with a liquid silicone overmolding material with better compatibility, it was found that the problem lay in the “adhesion” parameter – high-quality materials, through formula optimization, can firmly adhere to substrates such as PC and stainless steel, and will not delaminate even after high-temperature sterilization.

In addition to adhesion, the “temperature resistance range” also has many considerations. Take the automotive electronics field as an example. Components often need to switch between -40℃ (outdoor temperature in severe winter) and 120℃ (temperature around the engine). If the temperature resistance range of liquid silicone overmolding is narrow, after alternating cold and heat, the material is prone to becoming brittle and cracking. However, reliable quality liquid silicone overmolding has a temperature resistance range covering -50℃ to 150℃, which can meet the needs of most industrial scenarios.

There is also the “fluidity” parameter, which directly affects the overmolding effect of products with complex structures. An enterprise in Dongguan that produces smart bracelets has learned a lesson: the previously used material had poor fluidity, so the overmolding on the edge of the bracelet case was always uneven in thickness, and there were even gaps due to insufficient glue. After replacing with liquid silicone with excellent fluidity, the material can fill tiny gaps like water, making the edges and corners of the finished product round and uniform.

If you want to avoid these pitfalls when purchasing liquid silicone overmolding, welcome to talk to Aobo Silicone Rubber – we specialize in optimizing core parameters to make the quality of overmolded products more stable. Click on the online customer service or call us to help you choose the right material and avoid more pitfalls~