We provide you with a number of areas of silicone product solutions

Silicone mold – silicone molding mass production – silicone product assembly one-stop OEM/OEM customization

Orui Liquid silicone supplier, to solve the various fields of silicone rubber products

LSR silicone supplier, 30 liquid injection molding machines, 300 silicone injection molding team

Silicone rubber mold according to 3D drawings customized, 500 moQ

Focus on medical silica gel parts, automotive silica gel parts, electronic 3C products silica gel miscellaneous

Silicone mold – silicone molding mass production – silicone product assembly one-stop OEM/OEM customization

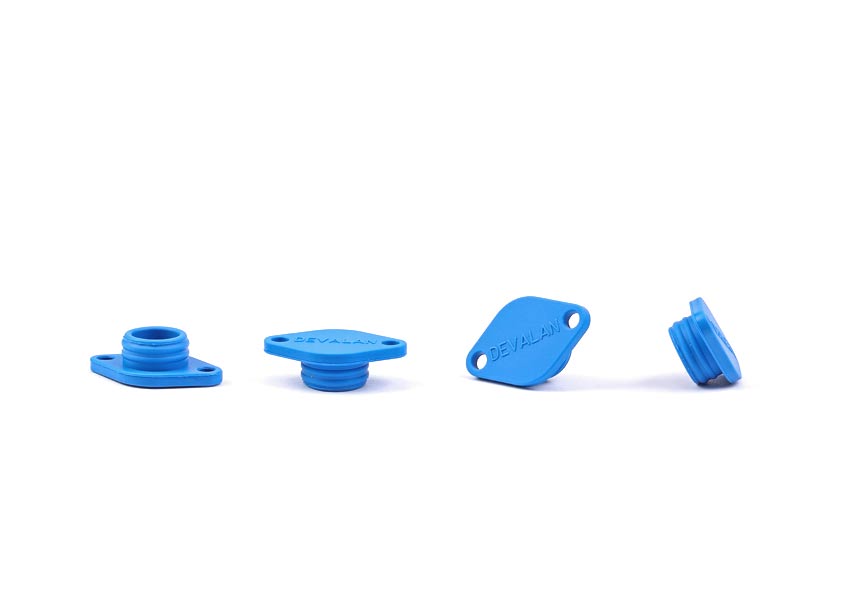

Silica gel sealing ring, precision up to 0.05mm, products used in electrical appliances, consumer electronics, industrial machinery products, functional sealing, wear resistance, high temperature resistance, long life, the material is food grade silica gel material, can pass FDA/LFGB certification, moQ 1000

Silicone rubber delivers the strength, temperature resistance, and durability needed under the bonnet and helps provide cushioning, load bearing and protective shock absorption qualities to automotive interiors

Silicone rubber has played a key role in advancements in computer technology, telecommunications, consumer electronics, and power distribution.

Our facilities support both cleanroom and normal shop floor operations, depending on the nature of the product, which gives us the flexibility to tailor production to your project schedule and budget.

Silica gel kitchen appliances, the use of non-toxic health food grade silica gel material, products are used in silica gel spatula, silica gel place mat, silica gel baking, silica gel spatula, silica gel ice, silica gel fresh bags and so on, can withstand high temperature 220 degrees, low temperature -40 degrees, easy to clean, adults and children can be applicable

rubber keypads also know as silicone keypads, which are ideal for a range of products. The average person comes in contact with silicone keypads, also known as elastomeric keypads, almost every single day. Because of their low cost, flexibility of design and reliability, silicone keypads are used in a variety of industries, including medical, marine, and military, in addition to consumer applications, such as TV remotes and electronic games.

Our holistic approach to Liquid Silicone Rubber molding relies on partnering with customers to develop innovative solutions based on unique specifications and requirements.

Rubber extrusion is generally preferred for continuous series of articles because it is cost-effective and requires short lead times to produce large batches. It is used in several applications to make tubes and rods, oven seals, electrical cables and wire insulation, gaskets, seals and more complex profiles.

Characteristics of silicone cover: wear resistance, aging resistance, high temperature resistance, waterproof, dustproof, high temperature resistance of 220 degrees and low temperature resistance of – 40 degrees. It is applied to automobile, medical treatment, industry, electronics, agriculture, daily necessities, etc. the precision can reach 0.01 tolerance. It can be processed and customized according to drawings and samples.

Our product range includes a wide range of silicone rubber tube, silicone braided tube, silicone transparent tube, silicone tube, silicone braided hose pipe and platinum cured silicone tubing.

We have passed ISO 9001:2015 and BSCI audit, and are in compliance with FDA, LFGB, Reach and RoHs in Europe. The main production of food, medical, industrial equipment, sealing parts and other silicone tube and silicone ring products.

Aorui silicone mold supplier has a large inventory of 3000 silicone molds, free mold opening, processing and customization of drawings and samples, 500 orders, 300 production team, fast delivery and punctual delivery

Aorui silicone pad supplier has a large inventory of 3000 silicone pads, free mold opening, processing and customization of drawings and samples, 500 orders, 300 production team, fast delivery and punctual delivery.

AOBO (Dongguan) precision silicone rubber products Co., Ltd., founded in 2008 (formerly known as Shenzhen Aorui silicone rubber products Co., Ltd.), is an entity manufacturer specializing in precision silicone rubber mold design – precision silicone rubber mold manufacturing – precision silicone rubber molding and assembly and after-sales service for 22 years. The products are widely used in automobile / new energy automobile precision silicone rubber parts, medical equipment precision silicone rubber parts, medical consumables silicone products, mother and child silicone products, daily necessities gifts, wearing waterproof seals, etc. after years of continuous accumulation and excellent technology, the company has very rich experience in developing and producing solutions for the functionality and appearance of silicone products.

The factory consists of a strong engineering design team. We offer personalized services and supports for projects through all steps of product development. From conceptual design, silicone material selection, engineering, prototyping and testing, to final volume production and assembly